CHG-83 Silicone Anti-Mildew Adhesive Sealant

NEUTRAL SILICONE SEALANTS PREVENT MOLD GROWTH

- ● Ideal for sinks, tubs, showers, vanities, countertops, and more

- ● Waterproof seal that maintains strong flexibility and adhesion

- ● Formulated to fight mold and mildew

- ●Silicone Max 10.1 oz. Clear 100% Premium Kitchen and Bath Silicone Sealant

- ● All kinds of doors and Windows glass installation, sealing

Overview

CHO-83 Silicone Anti-Mildew Adhesive Sealant

Chngoo Premium Kitchen & Bath 100% CHO-83 Silicone Anti-Mildew Sealant provides maximum silicone performance to seal out water and moisture in kitchen and bath applications. For a long time using under the humidity circumstance, the kitchen and bathroom will cause many mildew problems. The accumulation of mold and mildew causes discoloration and can cause damage to bathroom accessories and surfaces. For this reason, anti-mold acetoxy silicone adhesive sealants are perfectly suited for many kitchen & bathroom products. Backed by a 20 year mold and mildew free guarantee. Acetoxy silicone seals will not become moldy even in the shower, around sinks and between counters and backsplashes, since this type of sealant contains a fungicide that helps reduce mold growth. Shower ready in just 30 minutes so you can use your shower sooner. It is shrink and crack proof with excellent surface adhesion to provide 100% waterproof seal.

Products Features

l Brand: CHO Mildew-Proof Sealant

l Executive Standard: JC / T885-2016

l Shrink & crack proof

l Interior use

l Mineral spirits clean-up

l Not paintable

l Cured sealant is mold & mildew resistant

Specification

Brand Name: CHNGOO

Model: CHO-83

RTV: Neutral Cure

Color: Transparent ,white, black, Grey, and other colors as request

Main Raw Material: 100% Silicone

Application: Sinks, tubs, showers, vanities, countertops, and more

OEM or ODM: Yes

Package: 24pcs/CTN

Certificate: MSDS

Shelf life: 12 Months

Place of Origin: Guangdong, China (Mainland)

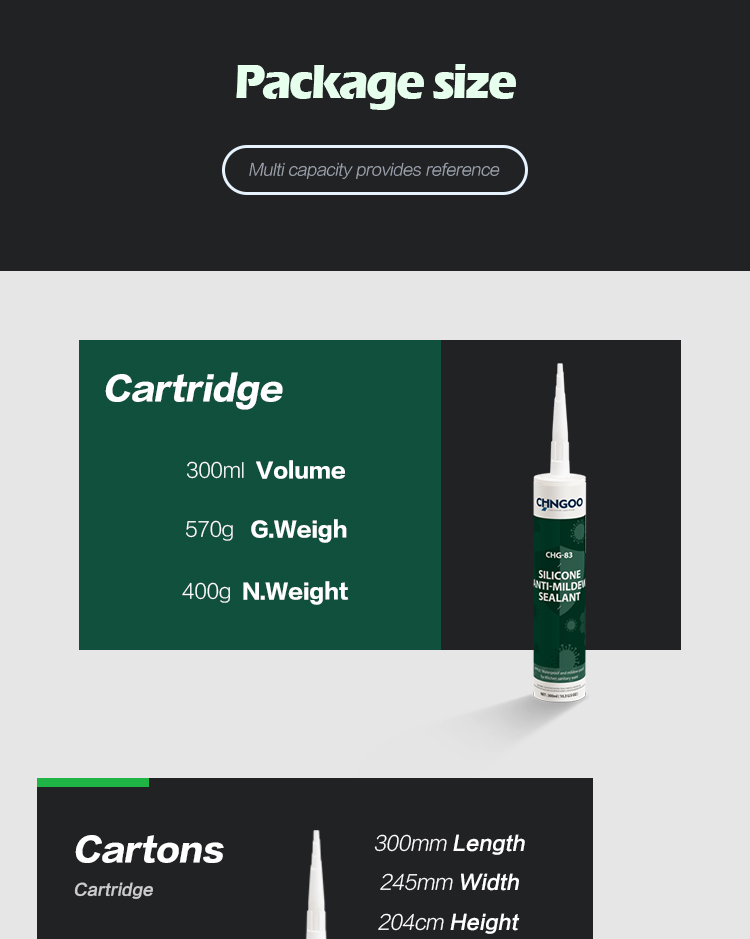

Package

Packaging Details

300ml/cartridge: 24 cartridges/carton; 1900 cartons/20' container without pallets; 1600 cartons with pallets

590ml/sausage: 1100 cartons/20' container

200L/drum: 75 drums/20'container

Preparation Stage

Ensure all the provided materials that bonding surfaces are clean and dry, SJ-168 neutral cure silicone adhesive has excellent unprimed adhesion to most substrates. Please confirm and test before buying the silicone sealant, make sure it is available for your using materials. If there is any doubt about contamination, surfaces should be solvent wiped with oil-free solvents, such as xylol, toluol, naphtha or non-flammable chlorinated solvents. Do not solvent-wipe with oil-based solvents such as Varsol. (Details please confirmed with sales).

Product Limitation

Be attention the following situations are not require for using:

1. Hide and semi-hide Glass curtain wall structural adhesive.

2. The grease, plasticizer or solvent surfaces.

3. The bad-ventilated places because it is required to absorb moisture in air to cure for the sealant.

4. Frosty or moist surface.

5. Continually soggy or humid place.

6. Surface temperature of materials under 4°C (39.2℉) or above 40°C (104℉).

7. Copper plated mirror, because it will be corrosive slightly on copper plating material.

|

No. |

Test Items |

Standard Regulation |

Test Result |

Assessment |

||

|

1 |

Appearance |

No clumps, gels, crusts, and precipitates that are not easy to disperse quickly and evenly. |

No clumps, gels, crusts, and precipitates that are not easy to disperse quickly and evenly. |

qualified |

||

|

2 |

Density,g/cm³ |

Specified value ±0.1 |

1.5 |

/ |

||

|

3 |

Crowd Out,mL/min |

≥50 |

265 |

qualified |

||

|

4 |

Tack-Free,h |

≤72 |

0.7 |

qualified |

||

|

5 |

Sag,mm |

vertical |

≤2 |

0 |

qualified |

|

|

Level |

0 |

qualified |

||||

|

6 |

Tensile bonding property, MPa |

M |

≤0.6 |

0.59 |

qualified |

|

|

G |

0.59 |

qualified |

||||

|

7 |

Elongation after hot air-water cycle |

M |

25% |

Non-destructive |

qualified |

|

|

G |

Non-destructive |

qualified |

||||

|

8 |

Elongation after water-ultraviolet irradiation |

25% |

Non-destructive |

qualified |

||

|

9 |

Low temperature flexibility |

-10℃ |

No cracking, delamination and adhesion damage |

qualified |

||

|

10 |

Elastic recovery rate after hot air-water cycle,% |

M |

≥5 |

94 |

qualified |

|

|

G |

98 |

qualified |

||||

|

11 |

Tensile Compression Cycle Performance |

M |

Durability rating |

7010,7005 |

7010 |

qualified |

|

Bonding failure area % |

≤25 |

0 |

||||

|

G |

Durability rating |

7010, 7005 |

7010 |

qualified |

||

|

Bonding failure area % |

≤25 |

0 |

||||

Test Report

|

No. |

Test Items |

Standard Regulation |

Test Result |

Assessment |

||

|

1 |

Appearance |

No clumps, gels, crusts, and precipitates that are not easy to disperse quickly and evenly |

No clumps, gels, crusts, and precipitates that are not easy to disperse quickly and evenly |

qualified |

||

|

2 |

Density,g/cm³ |

Specified value ±0.1 |

1.5 |

/ |

||

|

3 |

Crowd Out,mL/min |

≥50 |

265 |

qualified |

||

|

4 |

Tack-Free,h |

≤72 |

0.7 |

qualified |

||

|

5 |

Sag,mm |

vertical |

≤2 |

0 |

qualified |

|

|

Level |

0 |

qualified |

||||

|

6 |

Tensile bonding property, MPa |

M |

≤0.6 |

0.59 |

qualified |

|

|

G |

0.59 |

qualified |

||||

|

7 |

Elongation after hot air-water cycle |

M |

25% |

Non-destructive |

qualified |

|

|

G |

Non-destructive |

qualified |

||||

|

8 |

Elongation after water-ultraviolet irradiation |

25% |

Non-destructive |

qualified |

||

|

9 |

Low temperature flexibility |

-10℃ |

No cracking, delamination and adhesion damage |

qualified |

||

|

10 |

Elastic recovery rate after hot air-water cycle, % |

M |

≥5 |

94 |

qualified |

|

|

G |

98 |

qualified |

||||

|

11 |

Tensile Compression Cycle Performance |

M |

Durability rating |

7010,7005 |

7010 |

qualified |

|

Bonding failure area % |

≤25 |

0 |

||||

|

G |

Durability rating |

7010,7005 |

7010 |

qualified |

||

|

Bonding failure area % |

≤25 |

0 |

||||

PRODUCT Description

Used For

Related Products

GP-130 Acetic Window & Door Silicone Sealant

Silicone sealants that meet the demands of automated window and door manufacturing in a variety of colors

OS-796 Neutral Window & Door Silicone Sealant

Ensure resilient, long-lasting joint strength in new or remedial applications with OS-796 neutral silicone sealant.

SJ-168 Neutral Transparent Glass Curtain Wall Silicone Sealant

Neutral-cure silicone sealant suitable for a wide range of glazing, weathersealing and professional trade applications.

SJ-268 Neutral Construction-Grade Silicone Structural Adhesive Sealant

Silicone Structural Adhesive Sealant SJ-268

High Strength Silicone Epoxy Grouting Adhesive

High-Performance Epoxy Grouting Adhesive For Commercial And Residential Tile Installations

CONTACT US

Foshan Chngoo Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us