FP-996 Fire Resistant Neutral Silicone Adhesive

Neutral Fire-Resistant Silicone Sealant ensure to guard against damage from fire, smoke and toxic gasses.

- ● Sealing of perimeter, connection and expansion joints in the building industry.

- ● Fire-proof sealing for door and window installation

- ● Fire-proof sealing of curtain wall project

- ● Impregnated, varnished or painted wood.

- ● Metals (aluminium, steel, zinc, copper); concrete, mortar, masonry or brick.

- ● Public places waterproof, moisture - proof, decoration and other fire - proof sealing.

- ● Fire-proof sealing for indoor fire-proof partition and interior decoration

Overview

FP-996 Fire Resistant Silicone Adhesive

CHNGOO excellent fire-resistant silicone sealant provides an effective solution to combine joints together with a high movement capability, or where they are formed between dissimilar substrates, such as steel and masonry. The sealant widely used for fire-proof seal for interior decoration and indoor fire-proof partition, door and window installation, and different kinds of industrial uses. As a high specification product, the fire stopping sealant consists of one part alkoxy cure silicone, ensuring excellent un-primed adhesion to the majority of building surfaces. Easy to install, It helps control the spread of fire, smoke and toxic fumes within a given area surrounded by firewalls for a period of up to four hours, depending on joint configuration. Recommended for firestop sealing of interior and exterior building and construction movement joints or openings, where a fire rating of up to 4 hours is required.

Products Features

lNeutral curing, one-component

lExcellent weather and UV resistance

lExcellent extrusion and thixotropy between 4℃~+40℃

lExcellent adhesion to most substrates

lThe highest fire resistant level of GB 23864: A3

lLong Using Life.

Specification

Brand Name: CHNGOO

Model: FP-996

RTV: Neutral Cure

Color: Transparent ,white, black, Grey, and other colors as request

Main Raw Material: Silicone

Application: Metal, coated glass, concrete, marble,granite etc construction material.

OEM or ODM: Yes

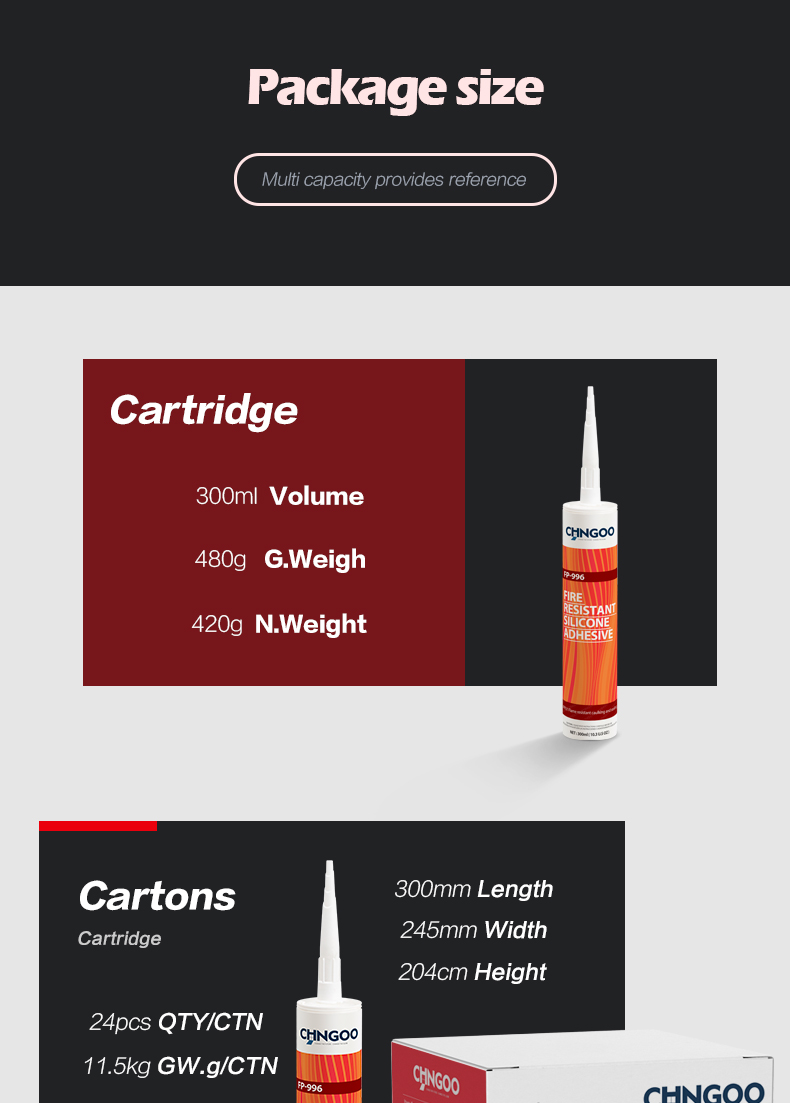

Package: 24pcs/CTN

Certificate: MSDS

Shelf life: 12 Months

Place of Origin: Guangdong, China (Mainland)

Package

Packaging Details

300ml/cartridge: 24 cartridges/carton; 1900 cartons/20' container without pallets; 1600 cartons with pallets

590ml/sausage: 1100 cartons/20' container

200L/drum: 75 drums/20'container

Preparation Stage

Ensure all the provided materials that bonding surfaces are clean and dry, SJ-168 neutral cure silicone adhesive has excellent unprimed adhesion to most substrates. Please confirm and test before buying the silicone sealant, make sure it is available for your using materials. If there is any doubt about contamination, surfaces should be solvent wiped with oil-free solvents, such as xylol, toluol, naphtha or non-flammable chlorinated solvents. Do not solvent-wipe with oil-based solvents such as Varsol. (Details please confirmed with sales).

Product Limitation

Be attention the following situations are not require for using:

1. Hide and semi-hide Glass curtain wall structural adhesive.

2. The grease, plasticizer or solvent surfaces.

3. The bad-ventilated places because it is required to absorb moisture in air to cure for the sealant.

4. Frosty or moist surface.

5. Continually soggy or humid place.

6. Surface temperature of materials under 4°C (39.2℉) or above 40°C (104℉).

7. Copper plated mirror, because it will be corrosive slightly on copper plating material.

|

No. |

Test Items |

Standard Regulation |

Test Result |

Assessment |

||

|

1 |

Appearance |

No clumps, gels, crusts, and precipitates that are not easy to disperse quickly and evenly. |

No clumps, gels, crusts, and precipitates that are not easy to disperse quickly and evenly. |

qualified |

||

|

2 |

Density,g/cm³ |

Specified value ±0.1 |

1.5 |

/ |

||

|

3 |

Crowd Out,mL/min |

≥50 |

265 |

qualified |

||

|

4 |

Tack-Free,h |

≤72 |

0.7 |

qualified |

||

|

5 |

Sag,mm |

vertical |

≤2 |

0 |

qualified |

|

|

Level |

0 |

qualified |

||||

|

6 |

Tensile bonding property, MPa |

M |

≤0.6 |

0.59 |

qualified |

|

|

G |

0.59 |

qualified |

||||

|

7 |

Elongation after hot air-water cycle |

M |

25% |

Non-destructive |

qualified |

|

|

G |

Non-destructive |

qualified |

||||

|

8 |

Elongation after water-ultraviolet irradiation |

25% |

Non-destructive |

qualified |

||

|

9 |

Low temperature flexibility |

-10℃ |

No cracking, delamination and adhesion damage |

qualified |

||

|

10 |

Elastic recovery rate after hot air-water cycle,% |

M |

≥5 |

94 |

qualified |

|

|

G |

98 |

qualified |

||||

|

11 |

Tensile Compression Cycle Performance |

M |

Durability rating |

7010,7005 |

7010 |

qualified |

|

Bonding failure area % |

≤25 |

0 |

||||

|

G |

Durability rating |

7010, 7005 |

7010 |

qualified |

||

|

Bonding failure area % |

≤25 |

0 |

||||

Test Report

|

No. |

Test Items |

Standard Regulation |

Test Result |

Assessment |

||

|

1 |

Appearance |

No clumps, gels, crusts, and precipitates that are not easy to disperse quickly and evenly |

No clumps, gels, crusts, and precipitates that are not easy to disperse quickly and evenly |

qualified |

||

|

2 |

Density,g/cm³ |

Specified value ±0.1 |

1.5 |

/ |

||

|

3 |

Crowd Out,mL/min |

≥50 |

265 |

qualified |

||

|

4 |

Tack-Free,h |

≤72 |

0.7 |

qualified |

||

|

5 |

Sag,mm |

vertical |

≤2 |

0 |

qualified |

|

|

Level |

0 |

qualified |

||||

|

6 |

Tensile bonding property, MPa |

M |

≤0.6 |

0.59 |

qualified |

|

|

G |

0.59 |

qualified |

||||

|

7 |

Elongation after hot air-water cycle |

M |

25% |

Non-destructive |

qualified |

|

|

G |

Non-destructive |

qualified |

||||

|

8 |

Elongation after water-ultraviolet irradiation |

25% |

Non-destructive |

qualified |

||

|

9 |

Low temperature flexibility |

-10℃ |

No cracking, delamination and adhesion damage |

qualified |

||

|

10 |

Elastic recovery rate after hot air-water cycle, % |

M |

≥5 |

94 |

qualified |

|

|

G |

98 |

qualified |

||||

|

11 |

Tensile Compression Cycle Performance |

M |

Durability rating |

7010,7005 |

7010 |

qualified |

|

Bonding failure area % |

≤25 |

0 |

||||

|

G |

Durability rating |

7010,7005 |

7010 |

qualified |

||

|

Bonding failure area % |

≤25 |

0 |

||||

Fire resistant silicone sealant, also known as Polystyrene (PS) is a unique one-part, low-pressure, vented, liquid-stabilized silicone rubber liquid-vacuum product having excellent fire resistance properties. The product's exclusive Vented System can be used for indoor air and fuel combustion, vapor compression, as well as lubricating seals and joints. The high-pressure release from the sealant's high temperature gas expansion produces a chemical reaction with the moisture present in the surrounding atmosphere. This results in the evolution of friction and heat, which work together to cause the sealant to expand and reach its full potential, thus ensuring the complete sealing and protection of the surrounding area.

As compared to other types of fire resistant silicone sealants, the latest version of the product is the result of extensive research and technological developments undertaken by certain companies. One of the main contributing factors towards its development is the knowledge and technology of manufacturers that have made significant contributions towards the final development. A prime example of such an establishment is the Fireproof Polyethylene Corp (FPEC), a business unit whose existence spans over forty years. Among its many accomplishments, the company has been instrumental in bringing forth the design, manufacture, sale and distribution of fire-resistant silicone sealant.

If you are looking to purchase these fire resistant silicone sealants, you need to identify a good manufacturer or supplier of such products. Identifying a trustworthy manufacturer is not that difficult. You can start your search by either going straight to the manufacturer or supplier by using your favorite search engine or by referrals from people you know and trust. You may also want to consider the recommendations provided by online review sites.

PRODUCT Description

Used For

Related Products

GP-130 Acetic Window & Door Silicone Sealant

Silicone sealants that meet the demands of automated window and door manufacturing in a variety of colors

OS-796 Neutral Window & Door Silicone Sealant

Ensure resilient, long-lasting joint strength in new or remedial applications with OS-796 neutral silicone sealant.

SJ-168 Neutral Transparent Glass Curtain Wall Silicone Sealant

Neutral-cure silicone sealant suitable for a wide range of glazing, weathersealing and professional trade applications.

SJ-268 Neutral Construction-Grade Silicone Structural Adhesive Sealant

Silicone Structural Adhesive Sealant SJ-268

High Strength Silicone Epoxy Grouting Adhesive

High-Performance Epoxy Grouting Adhesive For Commercial And Residential Tile Installations

CONTACT US

Foshan Chngoo Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us