CHO-A3 Gaps & Cracks Polyurethane (PU) Form Sealant

Overview

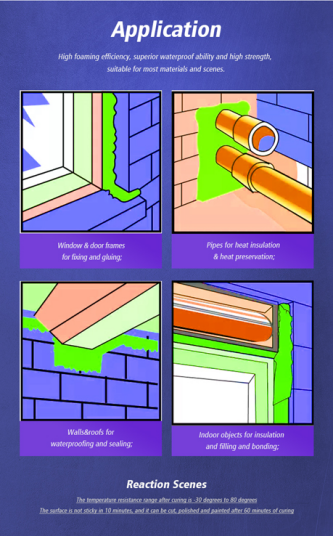

CHO-A3, one component PU foam, is an environmentally friendly and energy-saving building material with good surface activity and can reduce the surface tension of the liquid. After foaming and curing, it can achieve adhesion, sealing and leakage, which is recommended for wooden doors installation. It has the function of adhesion, fixation, installation, sound insulation, heat insulation, high insulation, sealing moisture proof, dust proof, gas isolation, filling structure gaps, engineering holes and various cracks, etc.(Please operate in strict accordance with our company's installation instruction and call our customer service department for details). The use of, as well as the sealing plugging and waterproofing between the walls. It is with good performance, which has excellent adhesive ability, vibration-resistance, anti-corrosion ability, quick curing time and high efficiency. The PU foam needs to be used as soon as possible after unsealing, and it should be sealed so that it can be used next time. It needs to be placed out of the reach of infants and young children, and it should not be exposed to direct sunlight to prevent it from attending curing. If the PU foam with a long opening time cannot be used as soon as possible, the foaming effect and sealing effect will be reduced after a long time. Therefore, once the PU foam is opened, it is not recommended to store the remaining PU foam for a long time.

Products Features

lNormal applicable temperature of the tank: +5C℃- +35℃.

lOptimum working temperature: +18℃ - +25℃.

lRange of temperature resistance of cured adhesive: -30℃- +80℃.

lQuick Curing: Tack free time in 10 min. The foam can be cut, polished or painted after curing for 60 minutes.

lStrong adhesion: It bonds well to most materials.( Teflon, silicone, etc not included.), Coating on the metal surface is needed if it is applied on metal.

lVibration-resistance: elastic and buffering.

lAnti - corrosion: Anti-weak acid, weak base and aging resistance

lHigh efficiency: Convenient to carry and use, saving time and effort.

lSafety: no damage to human after curing.

Package

Packaging Details

310ml/cartridge: 20 cartridges/carton; 1800 cartons/20' container without pallets; 1600 cartons with pallets

200L/drum: 75 drums/20'container

Storage considerations:

1) Inversion or side placement is strictly prohibited to avoid valve adhesion and affect normal use.

2)In order to avoid leakage caused by corrosion of the iron tank, It shall be placed in a dry and cool place, and shall not be stored in wet environment

Product Limitation

Be attention the following situations are not require for using:

1. Hide and semi-hide Glass curtain wall structural adhesive.

2. The grease, plasticizer or solvent surfaces.

3. The bad-ventilated places because it is required to absorb moisture in air to cure for the sealant.

4. Frosty or moist surface.

5. Continually soggy or humid place.

6. Surface temperature of materials under 4°C (39.2℉) or above 40°C (104℉).

7. Copper plated mirror, because it will be corrosive slightly on copper plating material.

|

No. |

Test Items |

Standard Regulation |

Test Result |

Assessment |

||

|

1 |

Appearance |

No clumps, gels, crusts, and precipitates that are not easy to disperse quickly and evenly. |

No clumps, gels, crusts, and precipitates that are not easy to disperse quickly and evenly. |

qualified |

||

|

2 |

Density,g/cm³ |

Specified value ±0.1 |

1.5 |

/ |

||

|

3 |

Crowd Out,mL/min |

≥50 |

265 |

qualified |

||

|

4 |

Tack-Free,h |

≤72 |

0.7 |

qualified |

||

|

5 |

Sag,mm |

vertical |

≤2 |

0 |

qualified |

|

|

Level |

0 |

qualified |

||||

|

6 |

Tensile bonding property, MPa |

M |

≤0.6 |

0.59 |

qualified |

|

|

G |

0.59 |

qualified |

||||

|

7 |

Elongation after hot air-water cycle |

M |

25% |

Non-destructive |

qualified |

|

|

G |

Non-destructive |

qualified |

||||

|

8 |

Elongation after water-ultraviolet irradiation |

25% |

Non-destructive |

qualified |

||

|

9 |

Low temperature flexibility |

-10℃ |

No cracking, delamination and adhesion damage |

qualified |

||

|

10 |

Elastic recovery rate after hot air-water cycle,% |

M |

≥5 |

94 |

qualified |

|

|

G |

98 |

qualified |

||||

|

11 |

Tensile Compression Cycle Performance |

M |

Durability rating |

7010,7005 |

7010 |

qualified |

|

Bonding failure area % |

≤25 |

0 |

||||

|

G |

Durability rating |

7010, 7005 |

7010 |

qualified |

||

|

Bonding failure area % |

≤25 |

0 |

||||

Test Report

|

No. |

Test Items |

Standard Regulation |

Test Result |

Assessment |

||

|

1 |

Appearance |

No clumps, gels, crusts, and precipitates that are not easy to disperse quickly and evenly |

No clumps, gels, crusts, and precipitates that are not easy to disperse quickly and evenly |

qualified |

||

|

2 |

Density,g/cm³ |

Specified value ±0.1 |

1.5 |

/ |

||

|

3 |

Crowd Out,mL/min |

≥50 |

265 |

qualified |

||

|

4 |

Tack-Free,h |

≤72 |

0.7 |

qualified |

||

|

5 |

Sag,mm |

vertical |

≤2 |

0 |

qualified |

|

|

Level |

0 |

qualified |

||||

|

6 |

Tensile bonding property, MPa |

M |

≤0.6 |

0.59 |

qualified |

|

|

G |

0.59 |

qualified |

||||

|

7 |

Elongation after hot air-water cycle |

M |

25% |

Non-destructive |

qualified |

|

|

G |

Non-destructive |

qualified |

||||

|

8 |

Elongation after water-ultraviolet irradiation |

25% |

Non-destructive |

qualified |

||

|

9 |

Low temperature flexibility |

-10℃ |

No cracking, delamination and adhesion damage |

qualified |

||

|

10 |

Elastic recovery rate after hot air-water cycle, % |

M |

≥5 |

94 |

qualified |

|

|

G |

98 |

qualified |

||||

|

11 |

Tensile Compression Cycle Performance |

M |

Durability rating |

7010,7005 |

7010 |

qualified |

|

Bonding failure area % |

≤25 |

0 |

||||

|

G |

Durability rating |

7010,7005 |

7010 |

qualified |

||

|

Bonding failure area % |

≤25 |

0 |

||||

Polyurethane form material, a lot of people in china think that polyurethane form is also a kind of resin, and even many businesses are confusing the concept, in fact, there is no relationship between the two, polyurethane form is just polyurethane form is not polyester resin, is not pu resin, only one name is called polyurethane form. On the one hand, because there is no filler, on the other hand, because the material toughness is much higher than the resin, not easy to break, the thickness is much lower than the resin, but the strength and toughness is higher than the resin, you can make a giant point. There is no need to add filler, so the dispersion of color paste is high, and it can produce gorgeous, warm and moist rock spots. Washed polyurethane form rock spots are like new ones, and resin points in this respect are far from being able to do. Non-toxic release during production.

Polyurethane form is a polymeric material made from diisocyanate, chain extender and oligomer polyol, which has the comprehensive properties of rubber and plastics. Its mechanical properties, abrasion resistance, oil resistance, tear resistance, chemical corrosion resistance, radiation resistance, good adhesion and other excellent properties, but its use temperature generally does not exceed 80℃, more than 100℃ material will soften deformation, mechanical properties significantly weakened, short-term use temperature does not exceed 120℃, seriously limited its application in the high temperature field

PRODUCT Description

Used For

Related Products

GP-130 Acetic Window & Door Silicone Sealant

Silicone sealants that meet the demands of automated window and door manufacturing in a variety of colors

OS-796 Neutral Window & Door Silicone Sealant

Ensure resilient, long-lasting joint strength in new or remedial applications with OS-796 neutral silicone sealant.

SJ-168 Neutral Transparent Glass Curtain Wall Silicone Sealant

Neutral-cure silicone sealant suitable for a wide range of glazing, weathersealing and professional trade applications.

SJ-268 Neutral Construction-Grade Silicone Structural Adhesive Sealant

Silicone Structural Adhesive Sealant SJ-268

High Strength Silicone Epoxy Grouting Adhesive

High-Performance Epoxy Grouting Adhesive For Commercial And Residential Tile Installations

CONTACT US

Foshan Chngoo Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us