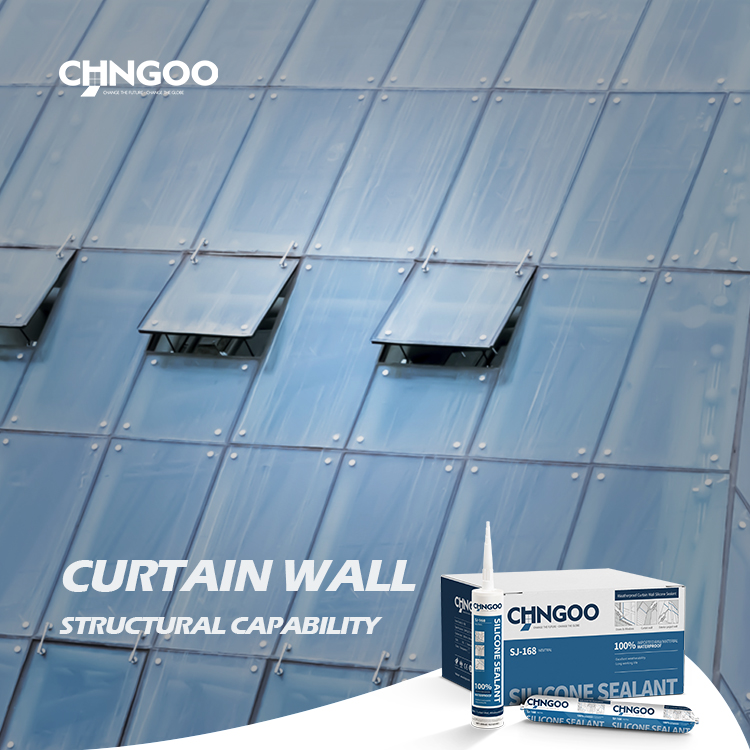

SJ-168 Neutral Transparent Glass Curtain Wall Silicone Sealant

Neutral-cure silicone sealant suitable for a wide range of glazing, weathersealing and professional trade applications.

- ● Sealing of joints between glass plates in a curtain wall structure.

- ● Sealing of perimeter, connection and expansion joints.

- ● Has an adhesive strength without primer materials.

- ● Impregnated, varnished or painted wood.

- ● Metals (aluminium, steel, zinc, copper); concrete, mortar, masonry or brick.

- ● Concrete and cement constructions.

- ● Marble ground and wall.

Overview

SJ-168 is used to seal building joints to prevent the penetration of rain, air and noise. It effectively weatherproofs junctions of building materials and can also excellent be used for sealing small joints and fillets like curtain wall, mullion and other building construction joints, and for glazing steel and aluminum windows, painted and plastic coated wood windows, interior glass partitions ,skylights and many construction adhesive applications. With good performance, excellent adhesion and flexibily with high modulus and good tensile strength Permanent watertight bonds are made with this sealant, in combination with glass, ceramic, steel, plastics, and painted surfaces. In addition, many maintenance applications are possible where long life, reliability and sealing properties are required. Has many applications as an elastic adhesive between materials with dissimilar coefficients of expansion. To make a conclusion, our silicone construction sealants are designed to reduce the time you need to search an available product, and to reduce the cost of wasted product on the jobsite.

Products Features

● Neutral curing, non-corrosive curing system.

● No unpleasant odor during cure.

● Excellent resistance to weather, water.

● For use on: Glass, glass curtain wall, ceramics, metals, polycarbonate, plastics, etc.

● Good adhesion to most common building material.

● Excellent displacement ability.

● Long Using Life.

Specification

Brand Name: CHNGOO

Model: SJ-168

RTV: Neutral Cure

Color: Transparent, white, black, Grey, and other colors as request

Main Raw Material: Silicone

Application: Nonstructural Glass curtain wall, stone curtain wall, high grade window & door, metal structure engineering.

OEM/ODM: Yes

Package: 24pcs/CTN

Certificate: MSDS

Shelf life: 12 Months

Place of Origin: Guangdong, China (Mainland)

Package

Packaging Details

300ml/cartridge: 24 cartridges/carton; 1900 cartons/20' container without pallets; 1600 cartons with pallets

590ml/sausage: 1100 cartons/20' container

200L/drum: 75 drums/20'container

Preparation Stage

Ensure all the provided materials that bonding surfaces are clean and dry, SJ-168 neutral cure silicone adhesive has excellent unprimed adhesion to most substrates. Please confirm and test before buying the silicone sealant, make sure it is available for your using materials. If there is any doubt about contamination, surfaces should be solvent wiped with oil-free solvents, such as xylol, toluol, naphtha or non-flammable chlorinated solvents. Do not solvent-wipe with oil-based solvents such as Varsol. (Details please confirmed with sales).

Product Limitation

Be attention the following situations are not require for using:

1. Hide and semi-hide Glass curtain wall structural adhesive.

2. The grease, plasticizer or solvent surfaces.

3. The bad-ventilated places because it is required to absorb moisture in air to cure for the sealant.

4. Frosty or moist surface.

5. Continually soggy or humid place.

6. Surface temperature of materials under 4°C (39.2℉) or above 40°C (104℉).

7. Copper plated mirror, because it will be corrosive slightly on copper plating material.

|

No. |

Test Items |

Standard Regulation |

Test Result |

Assessment |

||

|

1 |

Appearance |

No clumps, gels, crusts, and precipitates that are not easy to disperse quickly and evenly. |

No clumps, gels, crusts, and precipitates that are not easy to disperse quickly and evenly. |

qualified |

||

|

2 |

Density,g/cm³ |

Specified value ±0.1 |

1.5 |

/ |

||

|

3 |

Crowd Out,mL/min |

≥50 |

265 |

qualified |

||

|

4 |

Tack-Free,h |

≤72 |

0.7 |

qualified |

||

|

5 |

Sag,mm |

vertical |

≤2 |

0 |

qualified |

|

|

Level |

0 |

qualified |

||||

|

6 |

Tensile bonding property, MPa |

M |

≤0.6 |

0.59 |

qualified |

|

|

G |

0.59 |

qualified |

||||

|

7 |

Elongation after hot air-water cycle |

M |

25% |

Non-destructive |

qualified |

|

|

G |

Non-destructive |

qualified |

||||

|

8 |

Elongation after water-ultraviolet irradiation |

25% |

Non-destructive |

qualified |

||

|

9 |

Low temperature flexibility |

-10℃ |

No cracking, delamination and adhesion damage |

qualified |

||

|

10 |

Elastic recovery rate after hot air-water cycle,% |

M |

≥5 |

94 |

qualified |

|

|

G |

98 |

qualified |

||||

|

11 |

Tensile Compression Cycle Performance |

M |

Durability rating |

7010,7005 |

7010 |

qualified |

|

Bonding failure area % |

≤25 |

0 |

||||

|

G |

Durability rating |

7010, 7005 |

7010 |

qualified |

||

|

Bonding failure area % |

≤25 |

0 |

||||

Test Report

|

No. |

Test Items |

Standard Regulation |

Test Result |

Assessment |

||

|

1 |

Appearance |

No clumps, gels, crusts, and precipitates that are not easy to disperse quickly and evenly |

No clumps, gels, crusts, and precipitates that are not easy to disperse quickly and evenly |

qualified |

||

|

2 |

Density,g/cm³ |

Specified value ±0.1 |

1.5 |

/ |

||

|

3 |

Crowd Out,mL/min |

≥50 |

265 |

qualified |

||

|

4 |

Tack-Free,h |

≤72 |

0.7 |

qualified |

||

|

5 |

Sag,mm |

vertical |

≤2 |

0 |

qualified |

|

|

Level |

0 |

qualified |

||||

|

6 |

Tensile bonding property, MPa |

M |

≤0.6 |

0.59 |

qualified |

|

|

G |

0.59 |

qualified |

||||

|

7 |

Elongation after hot air-water cycle |

M |

25% |

Non-destructive |

qualified |

|

|

G |

Non-destructive |

qualified |

||||

|

8 |

Elongation after water-ultraviolet irradiation |

25% |

Non-destructive |

qualified |

||

|

9 |

Low temperature flexibility |

-10℃ |

No cracking, delamination and adhesion damage |

qualified |

||

|

10 |

Elastic recovery rate after hot air-water cycle, % |

M |

≥5 |

94 |

qualified |

|

|

G |

98 |

qualified |

||||

|

11 |

Tensile Compression Cycle Performance |

M |

Durability rating |

7010,7005 |

7010 |

qualified |

|

Bonding failure area % |

≤25 |

0 |

||||

|

G |

Durability rating |

7010,7005 |

7010 |

qualified |

||

|

Bonding failure area % |

≤25 |

0 |

||||

If you are having constructural silicone sealant project then definitely you would require the use of the sealants during construction, and there are two different types of them like the hot process sealants and the cold process sealants. Both of these sealants are being used for various construction related purpose like in the pipeline, the shaft, air handling system, power plant, oil platforms and many more. The main purpose of these sealants is to prevent the dust or the unwanted components from entering in the structure. So, if you are having construction project then definitely you would require the supply of the structural sealing products so that you can easily maintain your structure in the best possible way without affecting the durability of your construction work.

However, the question arises where you must get the supply of these sealing products and where you must get it manufactured. For this you need to do some research before selecting any particular manufacturer or supplier. You can even go to the consumer report directory and check that about the various consumer reports that are given regarding the company that you intend to buy the product from. This will help you know whether the company manufactures the material in a hygienic environment or not. Apart from this, you can also check with your local building codes and check whether the manufacturer of the material complies with the rules and regulations by using the appropriate construction sealant.

Once you are done with the selection of the company or supplier then obviously you must consider the price of the product. Therefore you must compare the prices of various manufacturers or suppliers of the same product and then choose the one who offers you a reasonable rate of the manufacturing cost. You can also check whether the supplier has the required experience in the field of construction related sealing or not. Moreover, you must also check that whether the supplier is providing with timely delivery of the product without compromising on the quality of the product. Thus, after considering all the factors above, you can easily select the right supplier and manufacture the construction sealants of your choice.

PRODUCT Description

Used For

Related Products

GP-130 Acetic Window & Door Silicone Sealant

Silicone sealants that meet the demands of automated window and door manufacturing in a variety of colors

OS-796 Neutral Window & Door Silicone Sealant

Ensure resilient, long-lasting joint strength in new or remedial applications with OS-796 neutral silicone sealant.

SJ-168 Neutral Transparent Glass Curtain Wall Silicone Sealant

Neutral-cure silicone sealant suitable for a wide range of glazing, weathersealing and professional trade applications.

SJ-268 Neutral Construction-Grade Silicone Structural Adhesive Sealant

Silicone Structural Adhesive Sealant SJ-268

High Strength Silicone Epoxy Grouting Adhesive

High-Performance Epoxy Grouting Adhesive For Commercial And Residential Tile Installations

CONTACT US

Foshan Chngoo Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us